PERFORMANCE TESTING

With so many foam inserts on the market these days and every brand having a performance story, how do you decide which is right for you. One of the ways we test Flat Tire Defender is a simple hammer impact test that virtually any consumer can duplicate. Yes, we do perform laboratory test using high tech equipment but we’ve found laboratory test do not always correlate to ‘real world’ conditions. Also, our rider survey’s have shown they primarily buy foam inserts as a way to protect rims. Yes, this is important but Flat Tire Defender does so much more. In the video you’ll notice when the hammer hits the foam it makes a different sound. Pay attention to the sound of FTD II. You’ll notice it’s much quieter. This correlates to how the foam absorbs wheel impact and rebounds quickly for the next impact. And how the FTD II material looks after impact. Enjoy the ride!

It’s Hammer Time!

FEATURES & BENEFITS

THERE IS EVEN MORE!

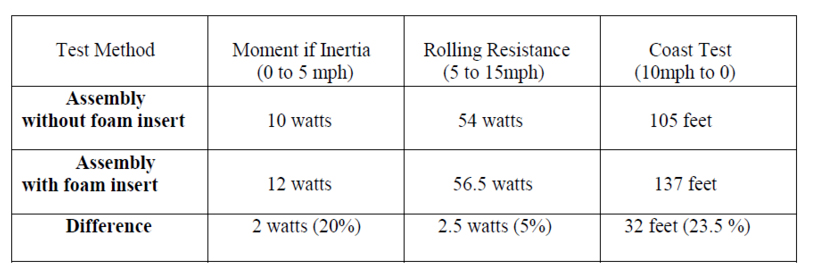

3RD PARTY LABORATORY TESTS

WHEEL ENERGY LABORATORY, NASTOLA, FINLAND – USING EXTREME TEST METHODS WITH STATE OF THE ART TEST DEVISES.

ROLLING RESISTANCE DEVISE – MEASURES MOMENT OF INERTIA AND ROTATING FRICTION IN WATTS

Procedure:

- 1200mm rotating drum with diamond plate surface

- Drum speed 0 to 15 mph

- Load 110lbs

- Coast testing on paved road with slight up hill – no wind – no chain – no brakes

- All tests using same type Alloy rim (28mm inner width), same type 27.5×2.50 tire, all 25 psi TLR with 4oz sealant.

Summary:

Using foam insert, requires slightly more effort to get out of the gate. Once at speed the watts are hardly measurable. Coast down test proved the biggest benefit and mirrored our test rider comments “foam insert help carry momentum thru corners and over rough terrain”.

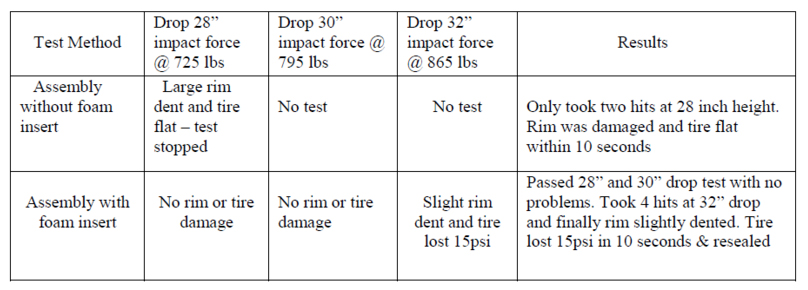

GUILLOTINE DEVISE – MEASURE SIDEWALL STRENGTH AND PINCH FLAT DEVISE:

Procedure:

All tests using same type Alloy rim (28mm inner width), same type 27.5×2.50 tire, all 25 psi TLR with 4oz sealant and 30 lb drop weight:

Summary:

Assembly without foam insert only managed two light hits before flatting. Assembly with foam insert took several hits at max height before losing air; allowing 20% higher impact force.

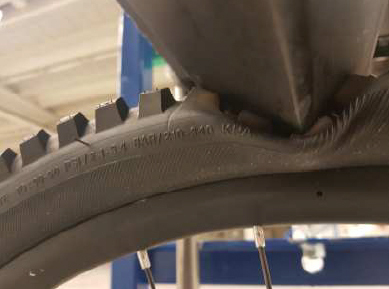

Foam Insert System – 28″ drop

Foam Insert System – 30″ drop

Foam Insert System – 32″ drop